Overview

Parallel conductors are commonly used for 400 amp and larger circuits (feeders) and utility services. Two or more sets of phase conductors are installed in separate conduits and electrically joined at both ends to form the equivalent a single conductor with a larger ampacity rating. Multiple parallel conductors dissipate heat better than a single larger gauge conductor. The smaller gauge conductors cost less and are easier to install. For example, a 1600 amp utility service might be installed using five conduits, with each conduit containing three 400 kcmil conductors, one for each phase. The A phase conductors from each conduit are connected together at the A phase lugs on the 1600 amp breaker and the other ends of the A phase conductors are connected together at the utility transformer. The B and C phase are connected in the same way. Selecting a CT window opening size that will fit around parallel conductors where they come together at the breaker is not easy. Without knowing the gauge and number of conductors, there arrangement, and spacing between conductors, about all you can do is make an educated guess. Note: There is a 15% restocking charge for returned equipment. To request help in selecting CTs, have an electrician open the panel, collect the above information, take photos of the location where the CTs would be installed, and send this information to tech.us@socomec.com

Single CT – All Conductors

The traditional way to measure sets of parallel conductors is with one CT large enough to fit around all the conductors. This method provides good accuracy but fitting the CTs around tightly spaced large conductors that are very rigid and hard to move can be tricky. At a main distribution panelboard (MDP) or breaker panel, CTs are typically installed where the parallel phase conductors all come together to terminate on lug of a breaker, disconnect, or bus-bar connection. The CT’s outside dimensions can also be a limiting factor because of the tight spacing between the three phases and neutral. CTs can also be installed around bus-bars but the spacing between bars and the distance from the back of the bus-bar to the enclosure’s back wall can be a concern.

While relatively more expensive then rigid magnetic CTs, flexible, rope-like Rogowski coils less than 0.5 inch thick will virtually fit in all situations. The coils are a snap to install, but first generation products require a signal conditioning module and DC power supply. As the technology improves, Rogowski coils will connect directly to meters and may eventually replace traditional iron CTs.

Multiple CTs – All Conductors

Another approach is to use individual CTs on each set of parallel phase conductors, and then connect the black and white CT wires from each parallel phase together at the meter’s CT input terminals corresponding to that phase. This is theoretically a good approach, but there are some reasons for concern:

- All parallel CTs must be exactly the same model part number: Different CT models have different internal burden resistors, so combining them in parallel will not work correctly.

- Increasing the number of CTs increases the risk of installing one CT backwards, having a loose connection, etc. Problems are more difficult to detect when using multiple CTs, because the error will only be a fraction of the total power.

- Connecting CTs in parallel has a negligible effect on accuracy. In fact, parallel operation tends to average out the nominal errors of the individual CTs.

- Multiple CTs may cost more than a single larger CT but installation is typically easier, which can reduces labor costs.

Computations

Note: The WattNode meter or monitoring equipment has no knowledge that multiple CTs are being used. There is no way to tell the WattNode meter that you have multiple CTs in parallel for each phase. So an effective CT amps value must be computed and used to get accurate measurements. If you use this approach, when configuring the WattNode meter or monitoring system, the effective CT rating (called CtAmps, nviCtAmps, nviCtAmpsF, etc.) for each phase will equal the rated CT amps for one CT times the number of CTs used for each phase. For example, if you use three 400A CTs for each phase, then the effective CtAmps will be 1200A.

Single CT – Multiple Conductors

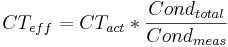

This approach applies if you can fit more than one of the parallel conductors into a single CT, but not all of them. For example, suppose each phase has six conductors, but the CT will only fit around four of the six conductors. This should work well, especially if you are monitoring more than half of the conductors. There could be minor current imbalance between conductors, but the effect should be negligible if you are measuring multiple conductors. You will need to scale the results in this case. The easiest way to scale them is to adjust the effective CT rated amps.

Computations

For example:

For example:

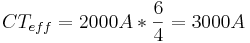

Single CT – Single Conductor

This approach is generally not recommended. It consists of installing one current transformer around one of the parallel conductors (for each phase). It is appealing, because you can use one CT per phase, saving money and simplifying the installation. You then correct the measured power by multiply by the number of parallel conductors. So if you are measuring just one conductor of four, you’ll want to multiple your measured current, power, and energy by four. The concern with this approach is that the current may not be equal in all conductors. This can be caused by variations in length between the conductors and variations in the connections at each end of the conductors. If the current is not equal in all conductors, then your readings may be consistently high or low. For some applications, such as demand management, this may not be a big concern. If you are using a single CT around one conductor, you may want to use a current probe or a power analyzer with current transformers to measure the current in the different conductors to verify that they are essentially identical. This can be tricky, because in the time it takes to move the probe from one conductor to another, the current could change.

Computations

Note: The WattNode meter or monitoring equipment does not have any knowledge of configurations like this. There is no way to tell the WattNode meter that you are monitoring only one of multiple feeders for each phase. So an effective CT amps must be computed and used to get accurate measurements. If you use this approach, when configuring the WattNode or monitoring system, the effective CT rating (called CtAmps, nviCtAmps, nviCtAmpsF, etc.) for each phase will equal the rated CT amps for one CT times the number of conductors for each phase. For example, if you use a single 400A CTs to measure one of three conductors making up a phase, then the effective CtAmps will be 1200A.