Contents |

Overview

The WattNode® Pulse meter generates contact-closure style pulse outputs. These are low frequency and low current, so the type of cable you use is generally not critical.

Long lengths of cable or the wrong type of cable may impact the ability of your pulse recording device to read pules accurately. Untwisted cable (multiconductor cables with more than two wires) or non-shielded cable will be more susceptible to interference. Very long lengths of cable will slow down pulse edges (rise and fall times) and may cause minor signal attenuation.

In addition to the suggestions in this article, you may want to contact the manufacture of your monitoring (or data logging) device for their cable type and length recommendations.

Cable Selection

You should consider the following:

- How many conductors do you need?

- Two for a single pulse output. Three if you are measuring bidirectional power/energy. Four if you are using Option P3 to monitor three channels. For longer runs, it is generally better to use one twisted pair of conductors for each pulse output; in this case, you would use three twisted pairs (six conductors) for three pulse channels.

- What wire gauge do you need?

- Because the current is normally less than 8 mA, any gauge should work except for extremely long distances. We recommend 24 AWG to 18 AWG for ease of use with the screw terminals. If the cable will be more than 1000 feet (300 m), you may want to use 20 AWG to 18 AWG wires.

- Do you need shielding?

- Generally not for short runs (less than 10 feet). For longer runs or if there is electrically noisy equipment nearby like variable speed drives, then you should use shielded cable and connect the shield to earth ground at one end.

- Do you need twisted wires?

- Yes, especially for non-shielded cable.

- What voltage rating do you need?

- We recommend wire or cable rated for the highest voltage present. So if you are monitoring a 208Y/120 Vac service, you should use 300 volt rated cable. If you are monitoring a 480Y/277 Vac service, use 600 volt rated cable. If you have the WattNode in a separate enclosure and there is no way the mains wires can contact the pulse output cable, then you could safely use lower voltage rated cable, such as 150 volt or lower. Long runs of 300 volt or 600 volt rated cable may be expensive, so it may be more economical to use lower voltage rated cable and use a protective jacket in the regions where the cable is in the vicinity of dangerous voltages.

- Can you run the pulse cable adjacent to or in the same conduit with mains wires?

- We strongly recommend against this. There may be interference from the high voltages and currents present on the mains wires, and if there is any insulation fault, arcing, etc. on the mains wires, it could put dangerous voltages on the low-voltage pulse cable.

Sample Cables

The following table lists some recommended 300V and 600V shielded cable. The prices are from 2010.

| Manufacturer | Part Num | Voltage Rating |

Wire Pairs/ Conductors |

AWG | Temperature Range |

UL / NEC | Supplier | Estimated Price |

Diameter |

|---|---|---|---|---|---|---|---|---|---|

| Carol | C2536A.41.10 | 600V | 1 / 2 | 16 AWG | -20°C to 75°C | UL 2106 NEC CL2, CM |

Digi-Key | – | 0.308″ |

| Alpha Wire | 3221 SL001 | 600V | 1 / 2 | 22 AWG | -55°C to 105°C | – | Digi-Key | $189 / 100ft | 0.181″ |

| Alpha Wire | 3231 SL001 | 600V | 1 / 2 | 20 AWG | -55°C to 105°C | – | Digi-Key | $215 / 100ft | 0.189″ |

| Tyco / Raychem | 44A1121-22-0/9-9 | 600V | 1 / 2 | 22 AWG | -65°C to 105°C | – | Newark | $509 / 328ft | 0.132″ |

| Tyco / Raychem | 44A1121-20-0/9-9 | 600V | 1 / 2 | 20 AWG | -65°C to 105°C | – | Newark | $570 / 328ft | 0.148″ |

| Belden | 9341 0101000 | 600V | 1 / 2 | 18 AWG | -30°C to 90°C | UL 1277 NEC TC |

Newark | $983 / 1000ft | 0.276″ |

| Belden | 9841 | 300V | 1 / 2 | 24 AWG | -30°C to 80°C | UL 2919 NEC CM |

Allied | $393 / 500ft | 0.232″ |

Cable Length Guidelines

How long can I make the pulse output cables?

There is no single answer to this question. In almost all cases, 500 ft (150 m) should work fine if you are using shielded, twisted-pair cable. In some cases, lengths of 4000 ft (1200 m) or more may work, although it is generally preferable to move the data collection device closer to the WattNode meter.

If you think you need more than 500 ft or you want greater certainty that your planned cable length won’t cause problems, the following analysis should help. Strong electromagnetic interference (EMI) may cause problems at any length, although shielded cable is relatively immune to EMI. You should also contact the manufacturer of your data collection equipment for their recommendations.

Determine Cable Capacitance

All cables have capacitance, which will slow pulse edges (longer rise time and fall time). If the cable is long enough, the capacitance may become so large that pulses are not detected correctly at the far end of the cable. Most cable datasheets list capacitance per foot (or meter). 20 to 30 pF/ft is common, so you could assume 30 pF/ft if you don’t have the exact value.

Once you have determined the capacitance or decided to use an estimated value, multiply that value by the length of your cable in feet. For example:

|

Cable capacitance per foot |

|

Cable length (feet) |

|

Total capacitance |

- Note: you do not need to multiply the cable capacitance by two, because only one of the two wires has a changing voltage. The common wire stays near ground potential at all times, so the capacitance of the common wire doesn’t affect the pulse edges.

- Note: One picofarad (pF) is 1.0e-12 farads.

Determine Pull-Up Resistance

The data logger will normally have an internal pull-up (or pull-down) resistor. You may be able to determine the value from a datasheet or manual, but it is also easy to determine with a multimeter and some simple measurements. Stronger pull-up resistors (lower resistance) will work better with long cable runs because the cable capacitance will have less effect. Very weak pull-up resistors, like 1.0 MΩ will limit the maximum cable length. For example, with a 1.0 MΩ pull-up resistor and a WattNode Pulse meter with a 4 Hz full-scale pulse frequency, you should probably limit your cable to something in the 400 to 800 foot range (120 to 240 m).

- Pull-Up Voltage (

): Set the multimeter to measure DC voltage. With the WattNode meter disconnected, measure between the common and the pulse input terminal on the data logger. This will determine the pull-up (or pull-down) voltage. Common values are 2.5 Vdc, 3.3 Vdc, 5.0 Vdc, 12 Vdc, and 24 Vdc.

): Set the multimeter to measure DC voltage. With the WattNode meter disconnected, measure between the common and the pulse input terminal on the data logger. This will determine the pull-up (or pull-down) voltage. Common values are 2.5 Vdc, 3.3 Vdc, 5.0 Vdc, 12 Vdc, and 24 Vdc.

- Short-Circuit Current (

): Set the multimeter to measure DC current (milliamp range): this generally requires moving the leads. With the WattNode meter disconnected, measure between the common and the pulse input terminal on the data logger. This determines the current that should flow through the WattNode pulse output when it is conducting.

): Set the multimeter to measure DC current (milliamp range): this generally requires moving the leads. With the WattNode meter disconnected, measure between the common and the pulse input terminal on the data logger. This determines the current that should flow through the WattNode pulse output when it is conducting.

- Pull-Up Resistance (

): Compute the effective pull-up resistance as follows:

): Compute the effective pull-up resistance as follows:

Determine Cable Resistance

You should be able to find the cable resistance  from the datasheet or http://en.wikipedia.org/wiki/American_wire_gauge. The actual resistance will be double that of a single conductor, because the current must travel from the data logger to the meter and then back again.

from the datasheet or http://en.wikipedia.org/wiki/American_wire_gauge. The actual resistance will be double that of a single conductor, because the current must travel from the data logger to the meter and then back again.

Generally, the cable resistance is negligible; 1000 feet of 24 AWG cable has 25Ω in each direction or 50Ω total, which is much lower than the typical pull-up resistor value and should have little effect on the pulse rise time or fall time.

The resistance will also cause some voltage drop in the cable:

You may want to compute this voltage drop to see if it will affect the data logger pulse detection. For example, with a 500 foot, 24 AWG cable, and a short-circuit current of 5 mA, the voltage drop in the cable will be 125 mV. Normally this won’t be an issue, but some data loggers are more sensitive to this.

Determine Pulse Rise-Time

Once you have determined the cable capacitance and the resistances, you can compute the approximate cable rise-time (use units of farads for the capacitance). We are using the approximation that the rise time is the same as the RC time constant.

For example, assuming a pull-up resistor value of 47kΩ and a 500 foot, 24 AWG cable with 30 pF/ft, we get the following:

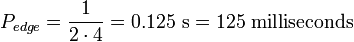

Next, we need to figure out if this will cause problems based on the maximum (or full-scale) pulse frequency. Most WattNode Pulse meters are sold with a full-scale pulse frequency of 4 Hz, but you can optionally purchase meters with pulse frequencies up to 600 Hz. Based on the full-scale pulse frequency, you can determine the pulse period. Each pulse period contains one rising and one falling edge, so if you divide the pulse period by two, you get the edge period (time between edges). Next, we want to compare this edge period to the pulse rise time we computed above.

|

Full-scale pulse output frequency (typically 4 Hz) |

|

Edge period (seconds) |

For example, with  = 4 Hz:

= 4 Hz:

The 0.7 millisecond cable rise time computed above is only 0.56% of 125 milliseconds, so the cable rise time won’t slow down the pulse edges enough to matter. Generally, the cable rise time should be no more than 10 to 20% of the edge period.

Note: The optoisolator (or solid-state relay) inside the WattNode Pulse meter also has rise and fall time parameters. These could be important in some cases. See the sections Pull-Up Resistor Selection and Specifications – Pulse Outputs in the WattNode Pulse Manual for details.

Fixes

If you discover that your cable length may cause problems, there are some solutions.

- If possible, move the data logger closer to the meter. This should also save on the cost of cabling.

- If you have any control over the pull-up resistor value, use a lower value resistor. This is easy with some data loggers and nearly impossible with others.

- Order the WattNode Pulse meter with a lower pulse output frequency: see WattNode Pulse – Option Hz.

- Try to order a cable with lower capacitance. The improvement will be limited, because you won’t be able to reduce the capacitance much (maybe 25-50%).

- Consider a wireless pulse transceiver solution; there are a few on the market.